I almost completed two sections today but because of the OAT probe supposed to get installed on the left side where the fuselage is resting on, I couldn't fully complete the second one yet.

The day started early due to the increasing heat. We are in the low 90s today. I started by tightening those nuts that hod the rudder pedals to the shelf. That's when I noticed that I couldn't bottom out the right pedal. It was interfering with the fuel return line at the mounting point of the ruder cables. It is really very tight in that tunnel. No room has been left unused. Fortunately I could bend the return line a bit to give the rudder arm enough clearance. I also tied the cable bundle to the return line to avoid interference with the wires and the rudder arm on the opposite side.

Then I hooked up the lines to the brake reservoir...

... and to the actual brakes.

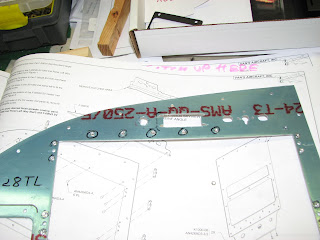

Then I went in the shop to start the work on the left and center panels. The left one needed some extended countersinking for the marked nutplate holes and for the mountain screws.

I also tried to find a home for my PCAS and I was hoping it would fit in that little spot above the ignition control. I added some markings on the panel to see how much clearance I had - if any.

As you can see, it's just not enough room to go there. I tried the right panel as the top center space will be reserved for the backup GCS.

Yep, that'll do! The work on this will have to wait until I have received my instruments. The Winter ASI with 510 degree arc is on special order as I wanted to get the markings done by the factory. I don't think the ASI will get here before next month. The altimeter should get here by next week. I found install sheets for Winter online, so I should be able to drill the mounting holes without having the actual instrument.

But before that I went back to the left side. The APDC switch hole had to get drilled. Positing was first.

And then it was drilled, using a #30 pilot hole and the step drill to open it up. All done on the drill press.

Please note that the plans are incorrect in asking for a 1/2" hole to be drilled. A 7/16" for the switch is totally sufficient.

It was time to countersink all the holes for the mounting screws AN507 #6.

Then I opened up the hole for the fuel pump switch that I intend to put where Van's had me put the APDC switch. I still think it's not easy to get to that location with the throttle being in the way. However, this is perfect for the fuel pump switch as this is usually supposed to be and stay on.

Back to the left panel. The stiffener angle had to get riveted to it. However, the APDC switch mounting nut would likely interfere with a small part of it. So I marked the area that should get removed.

The material was quickly removed with the SB wheels.

Then I riveted on the angle and the nutplates in the left and center panel.

Now it would be time to put the final finish on but I am not yet decided what to do and so I put them away for later. The right side needs the cut-outs done first anyway.

Looking ahead in the gear section, I found that a few steel parts could use some priming.

Then I spent some time cleaning up in the tunnel. Tightening cable-ties, snipping off the ends and final routing the static line in the tunnel.

The tailcone is still waiting for the brass screws to arrive, so except for tightening the cable-ties a bit, I left it alone.

I'm not sure what to do next. I could go back to the canopy but final finish would require the fuselage to be upright. I've identified some parts that need painting in the interior color and I still have some of the Steward paint left. Maybe I go ahead and do that, so it can cure over the hot and dry weekend.

I also still need to fit the end fairings for the rudder and the vertical stabilator. So that's also a choice for tomorrow.

Either way, I am getting close to putting the fuselage back on its belly.

Saturday, May 5, 2012

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment